MPL MACHINE SHOP

CONTACT

To reach shop personnel or confirm its location and hours, please click here.

RATES

UC San Diego-affiliated: $105/hr

Outside UC San Diego: $152/hr

ABOUT US

The Marine Physical Laboratory (MPL) Machine Shop was established in 1946 to support seagoing scientific groups with the design and fabrication of specialized oceanographic research equipment. After more than 70 years, the MPL Machine Shop has significant experience in the design and fabrication of scientific devices in support of oceanographic projects including precision optical equipment, sonar housings, precision deep sea pressure cases, winches, heave compensators, research equipment deployment, boom fabrication and a variety of marine equipment support devices.

The Shop also performs repairs on winches, cranes, hydraulic controls and a variety of special valves used in marine applications. In addition to all the fabrication and maintenance capabilities, The MPL shop handles all mooring operations for R/P FLIP during its numerous research expeditions.

MACHINE SHOP

The MPL Shop consists of 18,000 square feet of both inside and outside space. This space includes a large sophisticated CNC machining department capable of short run, long run and one-off precision parts as well as a sperate, fully equipped manual machining department. We have a wide variety of equipment from small Precision machines to large shipyard type machinery as well as an environmental test chamber, and special facilities for conducting equipment pressure tests. Please see below for a complete list of our special capabilities.

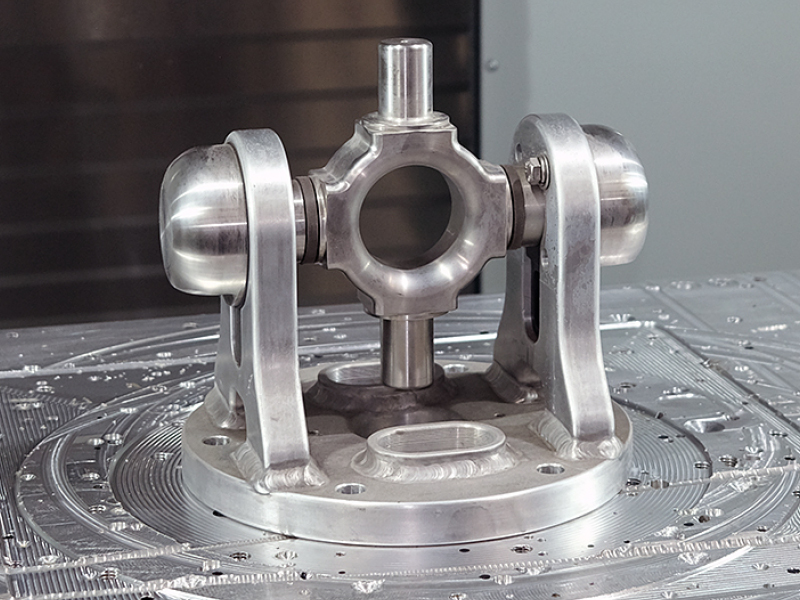

CNC

Our team of highly skilled programmers work in our dedicated programming department utilizing Mastercam 2023 CAM software to produce some of the most modern dynamic toolpaths for the CNC machines. We use the most current version of SolidWorks CAD software to create blueprints and solid models. The team has extensive knowledge working with hard to machine and exotic metals such as but not limited to titanium and stainless steel. We also have extensive knowledge machining softer metals such as aluminum, where we use high speed and feed dynamic toolpaths to achieve high material removal rates (MRR) which lowers machine time and cost.

CNC MILLS

- HASS VF-6SS CNC mill. Table travel Y32" x X64" x Z30"

- HASS VF-3 CNC mill. Table travel Y20" x X40" x Z25"

- 2 HAAS VF-2 CNC mills, Y20" x X30" x Z20" work window

- 3 4th axis rotary tables for HAAS mills

CNC LATHES

- HAAS SL10B CNC lathe, 2" thru spindle, 11" max diameter cut

- HAAS SL20B CNC lathe, 2.5" thru spindle, 11" max diameter cut

- HAAS SL30B CNC lathe, 3" thru spindle, 17" max diameter cut

- HAAS TL3B CNC lathe, 8.5" thru spindle, 30" max diameter cut

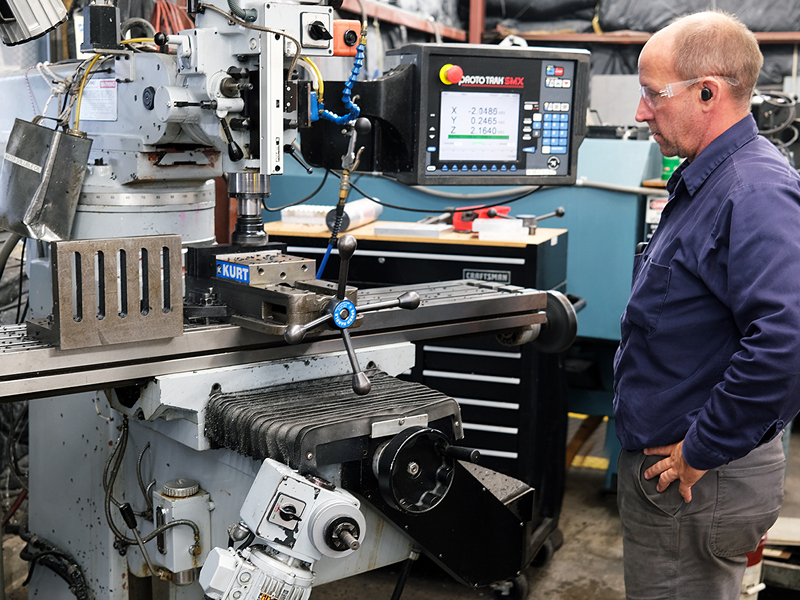

CONVENTIONAL MILLS

- 7 Bridgeport style mills with a two axis Proto Trac CNC controllers

- Ajax Horizontal / Vertical Mill, 18" X 78" table

- Lucas Model 42B-60 Boring Mill with a 40" X 86" table

CONVENTIONAL LATHES

- Manual lathes from Hardinge tool room lathe up to a Le Blond 10"

- LeBlond 8" Hollow Spindle Lathe

- LeBlond Hollow Spindle lathe with a 12" hole thru the headstock. The bed is a crank back style which will turn a 5' diameter piece 5' long or a 2' diameter piece 14' long over the carriage.

- Bullard Vertical Turret Lathe with a 50" table

WELD

- Inside TIG booth for welding/fabricating complex precision assemblies (aluminum, stainless, steel, titanium etc.)

OUTSIDE SHOP

The outside shop has the capabilities to weld various materials such as steel, stainless steel, aluminum, titanium, etc by MIG, TIG or ARC welding. The shop has a 7-1/2 ton bridge crane which spans entire shop area. Forklifts 4,000, 6,000 and 15,000 lbs. and a 12’ by 8’ F550 Diesel Flatbed truck. The pressure test chamber will test a piece 8" in diameter and 8' long to a pressure of 10,000 psi. Other equipment includes:

- 4' Press Brake

- 8' Hand Brake

- Rolling Machines to 6' long

- Buffalo Iron Worker

- Herr Voss plate shear 5/8" capacity 6' long on steel Darley Precision Sheet Metal Shear

- Large DoAll band saw

- Large Marvel auto feed band saw

For further information please visit our contact page by clicking here.

OUTPUT

Fabrication of 20-foot Liberdade class underwater autonomous fixed wing glider. MPL Shop fabricated the tight tolerance 6AL4V titanium frame spar pieces to fit both the elaborate welding fixture and thermal formed external skin.

On the left is a 60’ long aluminum boom fabricated by the MPL shop on large fixtures designed and built by the shop. This was a very thin wall boom fabricated by our welders and then tested on a fixture that simulated deployment at sea and certified by an outside Principal Engineering firm.

In the center is The SeaCycler, a prototype deep-ocean surface piercing profiler sensor built for Greg Siddall of the Bedford Institute of Oceanography. The MPL R&D shop worked closely with SIO’s Marine Science Development shop to produce the needed parts for the assembly. MPL produced the internal precision parts while the SIO shop produced the larger Sea Cycler housing. The parts involved were made to close tolerances.